Our eventual intention is to use such smart digital textiles to research cosmic dust, some of which has interplanetary or even interstellar origins. Consider if the protective material masking a spacecraft could double as an astrophysics experiment, but without including abnormal mass, quantity, or ability demands. What if this smart skin could also evaluate the cumulative injury caused by orbital space debris and micrometeoroids far too compact to be tracked by radar? Could sensored textiles in pressured spacesuits give astronauts a perception of contact, as if the material were being their own skin? In each and every circumstance, digital materials delicate to vibrations and cost could serve as a foundational technological know-how.

By now, engineered materials serve critical capabilities listed here on Earth. Geotextiles built of artificial polymers are buried deep underground to improve land embankments. Surgical meshes enhance tissue and bone in the course of invasive health-related processes.

In space, the outer walls of the ISS are wrapped in a protective engineered textile that provides the station its white shade. Known as Beta cloth, the woven material handles the station’s steel shell and shields the spacecraft from overheating and erosion. Beta cloth can also be observed on the exterior of Apollo-era spacesuits and

Bigelow Aerospace’s upcoming-era inflatable habitats. Until eventually it is feasible to substantially alter the human overall body itself, resilient textiles like this will continue to serve as a critical boundary—a second skin—protecting human explorers and spacecraft from the extremes of space.

Now it can be time to carry some smarts to this skin.

Our lab, the Responsive Environments Team at MIT, has been doing the job for properly above a decade on embedding distributed sensor networks into versatile substrates. In 2018, we were being knee-deep in establishing a significantly-out thought to grapple an asteroid with an digital world-wide-web, which would permit a community of hundreds or 1000’s of tiny robots to crawl throughout the surface as they characterised the asteroid’s materials. The technological know-how was curious to contemplate but not likely to be deployed at any time soon. Through a go to to our lab, Hajime Yano, a planetary scientist at the Japan Aerospace Exploration Agency’s Institute of Room and Astronautical Science, proposed a nearer-phrase risk: to turn the Beta cloth blanket employed on lengthy-period spacecraft into a science experiment. Consequently began a collaboration that has so significantly resulted in many rounds of prototyping and floor testing and two experiments in space.

One particular of the assessments is the impending start aboard the Cygnus NG-seventeen, funded by the

ISS National Laboratory. As the ISS orbits Earth, and the regional space surroundings changes, we will be triggering our sensors with known excitations to evaluate how their sensitivity may differ above time. Concurrently, we will just take impedance measurements, which will permit us peek into the interior electrical properties of the fibers. Any changes to the protective capabilities of the Beta material will be picked up using temperature sensors. If the program capabilities as created, we may possibly even detect up to twenty micrometeoroid impacts throughout the fabric’s 10-by-10-centimeter spot. A triggering program will flag any appealing info to be streamed to Earth in real time.

A second in-space experiment is already underway. For extra than a calendar year, a broader variety of our smart-material swatches has been quietly tucked away on a distinctive area of the ISS’s walls, on

Room BD’s Exposed Experiment Handrail Attachment Mechanism (ExHAM) facility. In this experiment, funded by the MIT Media Lab Room Exploration Initiative, the samples usually are not currently being powered. As an alternative, we’re checking their publicity to the space surroundings, which can be challenging on materials. They endure recurring cycles of severe heat and chilly, radiation, and material-eroding atomic oxygen. By means of real-time videography sessions we’ve been conducting with the Japan Aerospace Exploration Agency (JAXA), we’ve already witnessed symptoms of some anticipated discoloration of our samples. Once the samples return to Earth in late January by way of the SpaceX CRS-24 rocket, we will carry out a extra thorough analysis of the fabrics’ sensor general performance.

By demonstrating how to sleekly incorporate sensors into mission-crucial subsystems, we hope to motivate the prevalent adoption of digital textiles as scientific instrumentation.

Digital textiles acquired an early and auspicious start in space. In the nineteen sixties, the software for the Apollo direction laptop was saved in a woven substrate named main rope memory. Wires were being fed through conductive loops to point out 1s and about loops to point out 0s, acquiring a memory density of seventy two kilobytes for each cubic foot (or about two,500 kilobytes for each cubic meter).

All-around the similar time, a business named Woven Electronics (now element of Collins Aerospace) began establishing material circuit board prototypes that were being regarded properly ahead of their time. For a fleeting instant in computing, woven material circuits and main rope memory were being aggressive with silicon semiconductor technological know-how.

Digital materials then fell into a lengthy hiatus, until curiosity in wearable technological know-how in the nineties revived the idea. Our group pioneered some early prototypes, doing the job, for occasion, with Levi’s in the late ’90s on a jean jacket with an

embroidered MIDI keyboard. Since then, researchers and providers have developed a myriad of sensing systems in material, in particular for health and fitness-similar wearables, like versatile sensors worn on the skin that monitor your properly-currently being through your sweat, heart charge, and overall body temperature.

Additional lately, subtle fiber sensors have been pushing the general performance and capabilities of digital textiles even further. Our collaborators in the

Fibers@MIT group, for instance, use a producing procedure named thermal drawing, in which a centimeter-thick sandwich of materials is heated and stretched to submillimeter thickness, like pulling a multicolored taffy. Incredibly, the interior structure of the resulting fiber stays very exact, yielding purposeful units such as sensors for vibration, gentle, and temperature that can be woven instantly into materials.

But this exciting progress has not yet built its way to space textiles. Present-day spacesuits usually are not far too distinctive from the a person that Alan Shepard wore within Independence seven in 1961. New match styles have in its place concentrated on enhancing the astronaut’s mobility and temperature regulation. They could have contact-monitor-compatible fingertips, but that is about as subtle as the features will get.

In the meantime, Beta cloth has been employed on space habitats in extra or fewer its existing kind for extra than a 50 percent century. A smattering of material antennas and fiber-optic pressure sensors have been developed for rigid composites. But little has been performed to insert digital sensory functionality to the textiles we use in space.

To leap-start this exploration, our group has tackled three regions: We’ve crafted material sensors, we’ve labored with specialised facilities to receive a baseline of the materials’ sensitivity to effect, and we’ve created instrumentation to examination these materials in space.

We started out by upgrading Beta cloth, which is a Teflon-impregnated material built of versatile fiberglass filaments that are so densely woven that the material feels almost like a thick sheet of paper. To this protective layer, we desired to insert the ability to detect the tiny submillimeter or micrometer-scale impacts from cosmic dust. These microparticles move quickly, at speeds of up to fifty kilometers for each second, with an common speed of about 10 km/s. A 10-micrometer iron-dominant particle traveling at that speed incorporates about 75 microjoules of kinetic strength. It is just not a lot strength, but it can however have fairly a punch when concentrated to a compact effect spot. Studying the kinematics and spatial distributions of such impacts can give experts insight into the composition and origins of cosmic dust. What is extra, these impacts can bring about substantial injury to spacecraft, so we’d like to evaluate how repeated and energetic they are.

What type of material sensors would be delicate more than enough to decide up the indicators from these minuscule impacts? Early on, we settled on using piezoelectric fibers. Piezoelectric materials produce surface cost when subject matter to mechanical deformation. When a piezoelectric layer is sandwiched among two electrodes, it forms a sensor that can translate mechanical vibration into present-day. Piezoelectric effect sensors have been employed on spacecraft just before, but hardly ever as element of a material or as dispersed fibers.

One particular of the chief demands for piezoelectrics is that the electric dipoles within the material must all be lined up in purchase for the cost to accumulate. To completely align the dipoles—a procedure named poling—we have to utilize a substantial electric industry of about 100 kilovolts for each millimeter of thickness.

Early on, we experimented with weaving bare polyvinylidene difluoride yarn into Beta cloth. This single-material yarn has the advantage of currently being as fantastic and versatile as the fibers in apparel and is also radiation- and abrasion-resistant. As well as, the fiber-drawing procedure produces a crystalline phase structure that encourages poling. Implementing a hefty voltage to the material, although, caused any air trapped in the porous material to become electrically conductive, inducing miniature lightning bolts throughout the material and spoiling the poling procedure. We experimented with a slew of tricks to reduce the arcing, and we analyzed piezoelectric ink coatings used to the material.

Consider if the protective material masking a spacecraft could double as an astrophysics experiment, but without including abnormal mass, quantity, or ability demands.

Ultimately, although, we identified that multimaterial fiber sensors were being preferable to single-material yarns, since the dipole alignment demands to manifest only throughout the really tiny and exact distances within each and every fiber sensor, relatively than throughout a fabric’s thickness or throughout a material coating’s uneven surface. We selected two distinctive fiber sensors. One particular of the fibers is a piezoceramic nanocomposite fiber created by Fibers@MIT, and the other is a polymer we harvested from professional piezoelectric cabling, then modified to be suited for material integration. We coated these fiber sensors in an elastomeric conductive ink, as properly as a white epoxy that retains the fibers cool and resists oxidation.

To produce our material, we labored with space-textile maker

JPS Composite Products, in Anderson, S.C. The business served insert our two varieties of piezoelectric fibers at intervals throughout the material and ensured that our variation of Beta cloth however adhered to NASA specs. We have also labored with the Rhode Island College of Layout on material producing.

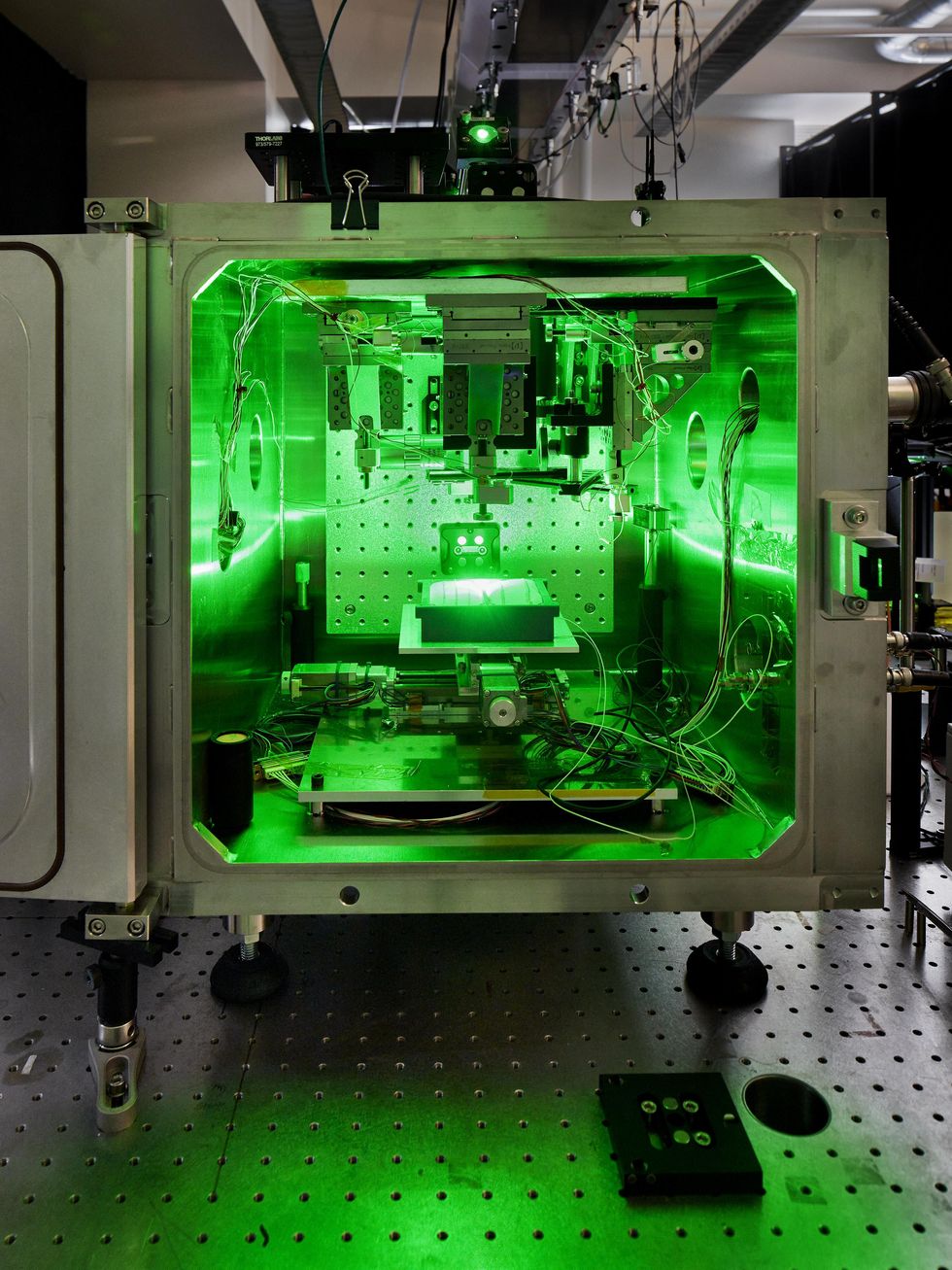

The green laser in the Laser-Induced Particle Impression Examination facility at MIT’s Institute for Soldier Nanotechnologies accelerates particles to supersonic speeds.Bob O’Connor

To examination the sensitivity of our material, we have been using the Laser-Induced Particle Impression Examination (LIPIT) platform created by Keith Nelson’s group at MIT’s

Institute for Soldier Nanotechnologies. This benchtop equipment is created for investigating how materials answer to microparticle impacts, such as in needle-absolutely free drug supply and chilly-sprayed industrial coatings. In our assessments, we employed the platform’s superior-speed particles to simulate space dust.

In a usual experiment, we distribute metal particles ranging from a handful of micrometers to tens of micrometers on to gold movie atop a glass substrate, which we connect with a launchpad. For each and every shot, a laser pulse vaporizes the gold movie, exerting an impulsive pressure on the particles and accelerating them to speeds of several hundreds of meters for each second. A superior-speed camera captures the effect of the gold particles on our target material swatch each handful of nanoseconds, equal to hundreds of millions of frames for each second.

So significantly, we’ve been able to detect electrical indicators not only when the particles struck a sensor’s surface but also when particles struck 1 or two cm away from the sensor. In some camera footage, it can be even feasible to see the acoustic wave developed by the indirect effect propagating along the fabric’s surface and finally reaching the piezoelectric fiber. This promising info suggests that we can space out our sensors throughout the material and however be able to detect the impacts.

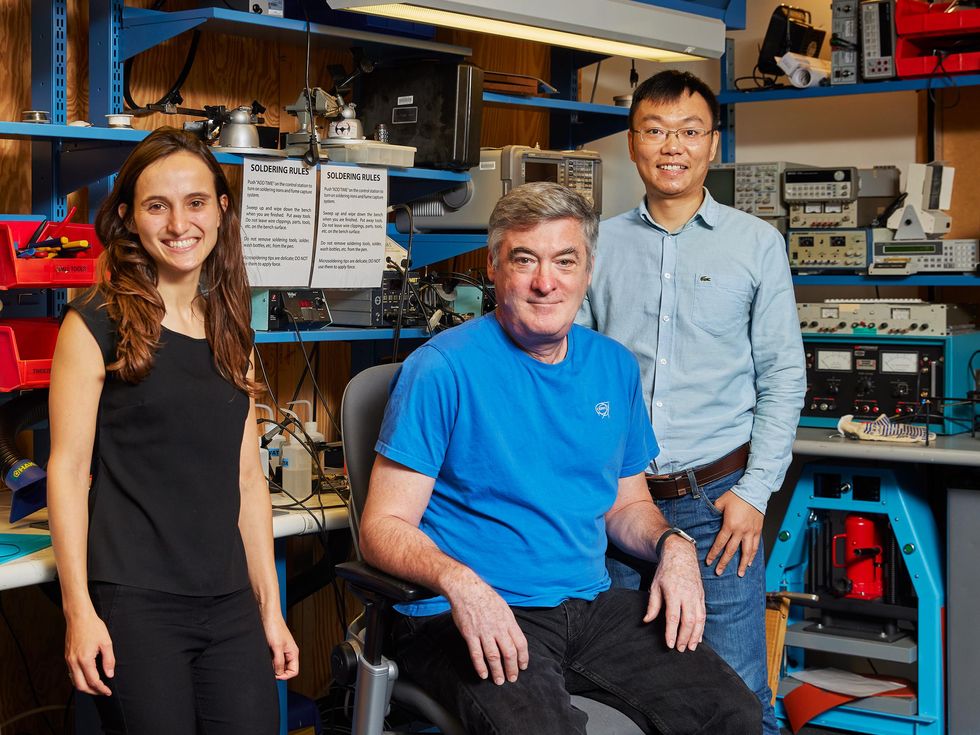

Juliana Cherston and Joe Paradiso of MIT’s Responsive Environments Team and Wei Yan of the Fibers@MIT group are element of the crew behind the smart-textile experiment launching in February.Bob O’Connor

Now we’re doing the job to nail down just how delicate the material is—that is, what ranges of particle mass and velocity it can register. We’re soon scheduled to examination our material at a Van de Graaff accelerator, which can propel particles of a handful of micrometers in diameter to speeds of tens of kilometers for each second, which is extra in line with interstellar dust velocities.

Beyond piezoelectrics, we’re also interested in detecting the plumes of electric cost that kind when a particle strikes the material at superior speed. All those plumes have clues about the impactor’s constituent aspects. One particular of our samples on the ISS is an electrically conductive artificial fur built of silvered Vectran fibers. Additional usually employed to enhance electrical cables, badminton string, and bicycle tires, Vectran is also a vital ingredient in inflatable spacecraft. In our circumstance, we created it like a carpet or a fur coat. We consider this design and style may possibly be properly suited to catching the plumes of cost ejected from effect, which could make for an even extra delicate detector.

In the meantime, there’s increasing curiosity in porting sensored textiles to spacesuits. A handful of members in our group have labored on a preliminary thought that employs materials made up of vibration, strain, proximity, and contact sensors to discriminate among a glove, metallic gear, and rocky terrain—just the kinds of surfaces that astronauts carrying pressurized fits would experience. This sensor info is then mapped to haptic actuators on the astronauts’ own skin, permitting wearers to vividly perception their surroundings proper through their fits.

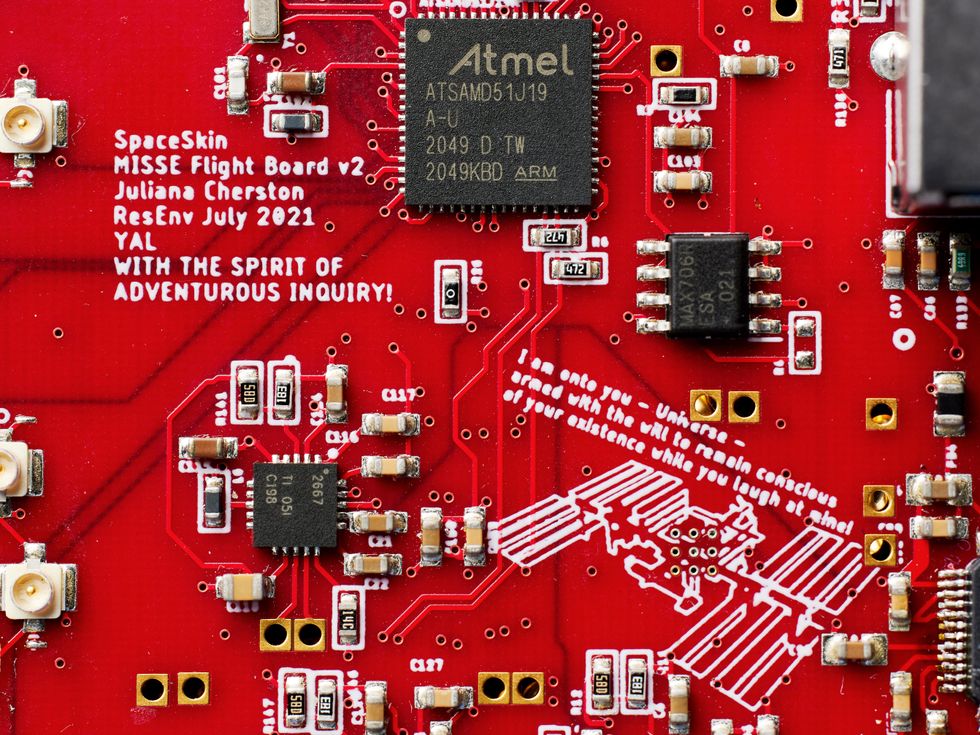

A close-up of the circuit board that will be employed to command the powered material sensors on the MISSE experiment.Bob O’Connor

How else could a sensor-increased material improve human engagement with the space surroundings? For lengthy-period missions, explorers residing for months within a spacecraft or habitat will crave experiential selection. Material and thin-movie sensors could detect the space weather conditions just outside the house a spacecraft or habitat and then use that info to alter the lighting and temperature within. A very similar program could even mimic certain exterior circumstances. Consider emotion a Martian breeze within a habitat’s walls or the contact of a cherished a person conveyed through a spacesuit.

To engineer a material that can survive severe circumstances, we foresee experimenting with piezoelectric materials that have intrinsic thermal and radiation resilience, such as boron nitride nanotubes, as properly as units that have superior intrinsic noise tolerance, such as sensors based mostly on glass fibers. We also envision setting up a program that can intelligently adapt to regional circumstances and mission priorities, by self-regulating its sampling prices, sign gains, and so on.

Room-resilient digital materials may possibly however be nascent, but the get the job done is deeply cross-reducing. Textile designers, materials experts, astrophysicists, astronautical engineers, electrical engineers, artists, planetary experts, and cosmologists will all have a role to perform in reimagining the exterior skins of potential spacecraft and spacesuits. This skin, the boundary of particular person and the demarcation of position, is real estate ripe for use.

This posting seems in the December 2021 print problem as “The Neatly Dressed Spacecraft.”

From Your Web site Content

Associated Content All-around the World wide web